There is alot of talk about using “safe” adhesives that are water-based or otherwise but a recent tweet by Roger Allen made me rethink the idea. Why not use no adhesives? The SP-7 table is a perfect example of this idea. It uses just tension & pressure to keep itself together, no adhesives, nails or anything. Its certainly a different way of looking at construction. I could imagine it would be easier to flat- ship these kinds of products as well; saving money and transportation energy. Whats your opinion on the idea? Does it seem like a valid green construction method to you?

Filed under: Uncategorized | Leave a Comment

Tags: adhesives, design, green, madsen, pressure, SP-7, Sustainable, table, tension

FSC Certified Lumber

While looking for materials to build a dining room table for my family I can across this FSC certified lumber at Home Depot. The FSC certifies companies that harvest their forests in a responsible manner. Most likely, these companies harvest their wood by selecting certain trees in the forest rather than clear cutting. This allows the forest to recover so when they come back the next time to cut another tree a new one has replaced what was cut beforehand. I also found that LEED points can be acquired by using FSC certified lumber in construction. Looks like a great way to harvest wood to me, Home Depot’s website says that one acre of FSC certified wood yields enough wood to build 5.65 2,000 square foot houses. Has anyone had any experience with this lumber or type of harvesting?

Filed under: Check this out, Materials | Leave a Comment

Tags: certified, design, FSC, FSC certification, green, Home Depot, LEED, Lumber, Nmadsen, sustainability, Sustainable, Wood

PLA Not so Sustainable

I met Emily Pilloton when she visited Auburn University on her trip around the country speaking about Project H Design. This meeting prompted me to take a look at her book and while flipping through Design Revolution I came across a section that outlined why PLA wasn’t as good or sustainable as I previously suspected. PLA is a plastic substitute that is made from corn and is completely compostable. Although PLA sounds like a great material and truly is compostable, Emily pointed out that out infrastructure isnt set up for it. For PLA to biodegrade it must be exposed to conditions that are present in a compost pile; a damp setting and temperatures that are 140 degrees or higher. A landfill does not have these conditions. This means that if you throw something made of PLA into the trash just like you would a traditional plastic item it will remain there just as long. The infrastructure simply doesn’t exist at the moment for PLA to be truly ground breaking.

I met Emily Pilloton when she visited Auburn University on her trip around the country speaking about Project H Design. This meeting prompted me to take a look at her book and while flipping through Design Revolution I came across a section that outlined why PLA wasn’t as good or sustainable as I previously suspected. PLA is a plastic substitute that is made from corn and is completely compostable. Although PLA sounds like a great material and truly is compostable, Emily pointed out that out infrastructure isnt set up for it. For PLA to biodegrade it must be exposed to conditions that are present in a compost pile; a damp setting and temperatures that are 140 degrees or higher. A landfill does not have these conditions. This means that if you throw something made of PLA into the trash just like you would a traditional plastic item it will remain there just as long. The infrastructure simply doesn’t exist at the moment for PLA to be truly ground breaking.

This brings up the point of completely understanding the life cycle of a product before you designate its material and sustainable status. PLA does have many advantages if a proper infrastructure existed, I know of some people that have personal composters that could take advantage of the material. What are your thoughts on the material? Do you think PLA has a future?

Filed under: Check this out, Interesting | Leave a Comment

Tags: compost, compostable, Design Revolution, Emily Pilloton, green, Pilloton, PLA, Sustainable

Cradle to Cradle – A Key Point

I just finished reading Cradle to Cradle, a well-known environmental book that focuses on sustainable design and how it can be accomplished. Instead of giving a brief synopses Im going to share a key point in the book that I found particularly interesting.

I just finished reading Cradle to Cradle, a well-known environmental book that focuses on sustainable design and how it can be accomplished. Instead of giving a brief synopses Im going to share a key point in the book that I found particularly interesting.

The idea of reusing technical nutrients– McDonough & Braungart suggest a way of reuse that I had never previously thought of. This is reusing the technical nutrients (like expensive metals and compounds) found in complex products. Cannon could design their cameras so that desired materials could easily be extracted and used to produce new cameras. Imagine being able to sell back your old camera to Cannon so that they could reuse the technical nutrients that would otherwise end up incinerated or in a landfill. Not only does the user benefit from this in the form of money but Cannon no longer needs to purchase expensive matterials. This stops the “cradle to grave” system and introduces a system that is closed looped and self-feeding.

All-in-all the book was definitely worth the read. McDonough & Braungart supply realistic solutions to very difficult and complex issues. Also, the book is quite positive and focuses on solutions rather than on how bad we are as consumers. If any of you have read the book what was your perception of it?

Filed under: Check this out, Interesting | 2 Comments

Tags: architecture, book, Braungart, C2C, cradle, cradle to cradle, design, environmental, green, green architecture, green design, McDonough, Michael Braungart, plastic book, sustainability, Sustainable, technical nutrient, William McDonough

Although I was already aware of the new Sun Chips compostable bags I had forgoten about them until last night at a party were I ran into them for the first time. Because of their strange feeling and noise (the new bags are considerably louder than the old ones) I became interested in what they were made of and the real story behind the bags. It turns out that the new bags are made from PLA, a plant based material that biodegrades when composted. The old bags were made from thin layers of polyolefin materials which are oil based and non-renewable. The new material, made mostly from corn, is replenished each year with the new crop.

Although I was already aware of the new Sun Chips compostable bags I had forgoten about them until last night at a party were I ran into them for the first time. Because of their strange feeling and noise (the new bags are considerably louder than the old ones) I became interested in what they were made of and the real story behind the bags. It turns out that the new bags are made from PLA, a plant based material that biodegrades when composted. The old bags were made from thin layers of polyolefin materials which are oil based and non-renewable. The new material, made mostly from corn, is replenished each year with the new crop.

I went searching around Sun Chip’s site and found a ton of great info on their research, testing, and construction of the new bags. The bag, 5 years in the making will now completely decompose in the correct conditions in about 14 weeks. Below is a link to the PDFs from Sun Chips that show some more of their work. So do you think this is a step in the right direction? I certainly do.

Filed under: Green Product | 1 Comment

Tags: chips, compost, compostable, design, green, sun, Sun chips, Sustainable

What is Eco-Friendly?

Recently I’ve been reading through “The Eco-Design Handbook” that is supposed to show products that are made in eco-friendly ways. However, instead of learning new ways of designing products to be more sustainable or green, Ive begun to question what it truly means to be “eco-friendly”

Recently I’ve been reading through “The Eco-Design Handbook” that is supposed to show products that are made in eco-friendly ways. However, instead of learning new ways of designing products to be more sustainable or green, Ive begun to question what it truly means to be “eco-friendly”

The book lists several products as eco-friendly because they are “durable” and “multifunctional”. Although I would say that these characteristics are valuable, I dont think those aspects alone classify a product as eco-friendly. Then comes the question: what does classify a product as truly eco-friendly or sustainable?

According to the Cradle to Cradle concept proposed by William Mcdonough and Michael Braungart, a product must be able to be completely biodegradable or reusable (a completely closed loop system) to be truly green. However, that seems a bit demanding to me, imagine making something as complex as a computer that could be totally broken down and recycled into the earth. Im not saying thats not something to strive for, it just seems a bit unrealistic.

Do you consider something that is durable and multifunctional green? Or do you agree with the cradle to cradle concept? Or somewhere in the middle? Where do you draw the line?

Filed under: Uncategorized | 2 Comments

Tags: design, eco, eco friendly, green, green movement, product, sustainability, Sustainable

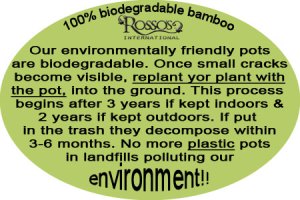

Biodegradable Pots

I came across this pot made by Rossos International that biodegrades within 6 months when thrown out. Made from bamboo and bamboo husks, Rossos International took advantage of a material that grows quickly enough to constantly replenish itself but is also biodegradable and useful.

I came across this pot made by Rossos International that biodegrades within 6 months when thrown out. Made from bamboo and bamboo husks, Rossos International took advantage of a material that grows quickly enough to constantly replenish itself but is also biodegradable and useful.

Filed under: Design, Green Product | Leave a Comment

Tags: bamboo, biodegradable, design, flower pot, green, sustainability, Sustainable, sustainable design

Coke Using Compostable Cups

Coke World in Atlanta, GA has an exhibition in which visitors can taste Coke products from all over the world. As you can imagine, people are going through lots of cups as they travel from kiosk to kiosk sampling different flavors from around the world. I was thankful to see that all of the cups were made from “100% renewable resources”. I believe the cups are made from PLA (polylactic acid) which is a plant based product (usually corn) and completely compostable. Great initiative by Coke to recognize and address and issue.

Coke World in Atlanta, GA has an exhibition in which visitors can taste Coke products from all over the world. As you can imagine, people are going through lots of cups as they travel from kiosk to kiosk sampling different flavors from around the world. I was thankful to see that all of the cups were made from “100% renewable resources”. I believe the cups are made from PLA (polylactic acid) which is a plant based product (usually corn) and completely compostable. Great initiative by Coke to recognize and address and issue.

UPDATE: After a little more research I found the cups are made by Nature Works LLC, a company that specializes in making products from materials that are organic (like plants and corn) rather than oil.

Filed under: Design, Green Product | Leave a Comment

Tags: alternative, cokacola, coke, coke world, cola, cups, green, PLA, soda, sustainability, Sustainable, sustainable design

Mio Wall Tiles

I just put up my wall tiles from Mio in my apartment. They are made of post and pre-consumer waste paper and designed to fit into each other in order to limit size and energy use when shipping. Also, materials for constructing the tiles are all locally sourced, meaning less energy is wasted in gathering materials for manufacturing.

I just put up my wall tiles from Mio in my apartment. They are made of post and pre-consumer waste paper and designed to fit into each other in order to limit size and energy use when shipping. Also, materials for constructing the tiles are all locally sourced, meaning less energy is wasted in gathering materials for manufacturing.

Filed under: Design, Green Product | Leave a Comment

Tags: design, eco, eco friendly, green, Mio, Mio culture, paper, sustainability, Sustainable, sustainable design, tiles, wall tiles, waste paper

Sustainable Buyers

The Sustainable Buyers idea was a response to the competition sponsored by renewableidea.co.uk that asked its competitors how buyers could shop and think more sustainably. My solution involved placing an icon next to an item’s price tag that designated how sustainably the product was produced based on MBDC’s principals. To read more about my solution click here. You can also vote for my idea here on the bottom of the page.

Filed under: Personal Work | Leave a Comment

Tags: design, eco, eco friendly, green, green design, idea, renewable, sustainability, Sustainable, sustainabliltiy